Commercial Phases

We are your translational development partner from concept to commercial.

We're experts at developing biomedical devices from early-stage concept generation and IP development, to device verification and validation, and design transfer programs into commercial manufacturing. Read more about each phase below.

Phase 4

A validated device is transferred into its commercial manufacturing process.

/Photos%20Finished/Video%20Capture%2000143%20(800%20x%20800).png?width=600&height=600&name=Video%20Capture%2000143%20(800%20x%20800).png)

Concept Generation

Our team translates clinical ideas into device concepts. We outline a compelling and executable business strategy, create a clear product concept with a detailed development plan, and identify risks appropriately. Projects begin with Concept Generation, but when ideas are sufficiently defined, they proceed directly to Concept Development.

Please feel out the form below and someone from our team will contact you shortly.

Concept Development

We refine and select device concepts to assess feasibility and gather feedback to understand the user experience. We design, build, and adjust alpha prototypes while conducting informal testing and analysis. We conduct Concept Development without design controls in place, but begin to establish design control documentation to support the design history file and subsequent design and development phases.

Please feel out the form below and someone from our team will contact you shortly.

Design & Development

We complete the design, prototyping, and testing process so that the product and subsystem specifications can be frozen and are testable and traceable. We optimize the design for manufacturability (DFM) and freeze the bill of materials. We complete Design & Development work under engineering-level design controls.

Please feel out the form below and someone from our team will contact you shortly.

Verification & Validation

During the Verification & Validation phase, we confirm that the product works as designed and meets the user's needs through objective evidence. We ensure that the product meets requirements for functionality, reliability, usability, and safety through rigorous verification and validation testing. We complete engineering builds, packaging design, labeling, human factors testing, manufacturing tooling and equipment, and pilot production builds.

Please feel out the form below and someone from our team will contact you shortly.

/Photos%20Finished/SERES%20PQ%20(8)_1%20Color%20(800%20x%20800).png?width=600&height=600&name=SERES%20PQ%20(8)_1%20Color%20(800%20x%20800).png)

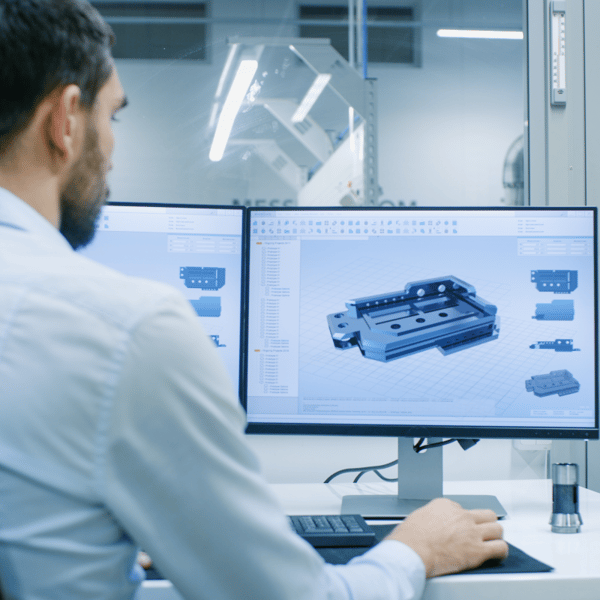

Design Transfer

We transfer validated products into their commercial manufacturing setting and support process verification and validation. During Design Transfer tooling, process verification and validation, and risk management are completed. We set up products for ongoing commercial production and quality control with the manufacturing partner.

Please feel out the form below and someone from our team will contact you shortly.

.webp)

.png?width=401&height=401&name=Logo%20-%20Just%20Mighty%20-%20White%20Logo%20(400%20x%20400).png)

%20-%20Tint%20100.png?width=664&height=226&name=Logo%20-%20Design%20by%20Boyd%20-%20Green%20(689%20x%20250)%20-%20Tint%20100.png)